ZIMMERMANN PV-Stahlbau

Your manufacturer for ground-mounted solar mounting frames – worldwide!

On the following pages you can find out more about us, our range of products and our know-how with ground-mounted solar mounting frames. Get an overview of our service portfolio. From planning to the last screw of the mounting frame, you will receive everything from one source – and a suitable solution for every project.

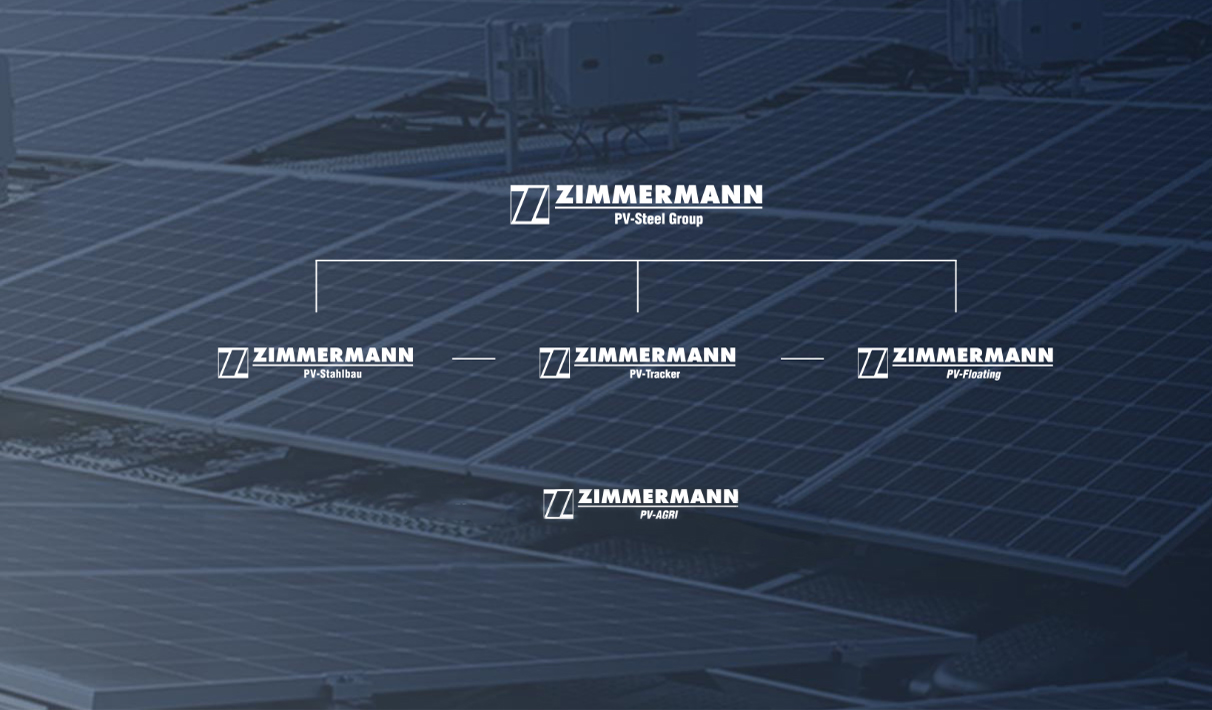

We are ZIMMERMANN

– the PV-Steel Group

The ZIMMERMANN companies include the branches PV-Stahlbau, PV-Tracker, PV-Floating, PV-Agri, stable fit outs and equipment, and metalworking. Cooperation between the various business segments fosters innovative ideas and developments across the business.

Our products are designed and manufactured with German precision and sold through our own global network and partner companies around the world.

ZIMMERMANN’s highly qualified employees utilise the best raw materials available to produce our solutions using precise, fully automated, state-of-the-art manufacturing and production facilities

ZIMMERMANN guarantees our global customers top quality at market-driven prices!

Full service with Swabian precision

At our production site in Ritzenweiler, Upper Swabia, we maintain a large raw material warehouse and very modern machinery. We have more than 8,000 tons of various sheet metal and pipes in a wide range of grades and dimensions in stock. This means that we are always well positioned for upcoming projects and can react quickly to tight delivery deadlines for larger quantities. Thanks to our tube and sheet metal laser systems, you can rely on innovative and precisely executed solutions.

Product overview

Quality and service

Made in Germany!

Precision through CNC tube laser technology with company headquarters in Oberessendorf and production halls in Ritzenweiler.

Top-Innovator 2020

Since 19 June ZIMMERMANN PV-Stahlbau has been one of the TOP 100 most innovative medium-sized companies in Germany.

Affordable

Computer-controlled machines and production facilities are a guarantee for "top quality" at reasonable prices!

Quick mounting

Fast assembly due to few components and reduced use of tools.

Durable

Robust due to strong materials, no welded joints and hot-dip galvanizing.

Certified Quality

The products we put on the market are CE-conform / Organization is ISO9001 and ISO14001 certified.

Worldwide delivery

Precise and fully automatic production with headquarters in Oberessendorf and production halls in Ritzenweiler.

Variable and individual

Individual adaptation to module size and local conditions as well as adjustable inclination and height.

News

Career fair Ravensburg on 25 April 2024 11-7pm

ZIMMERMANN PV-Steel Group awarded as TOP employer

InterSolar Europe in Munich, Germany, 19 – 21 June 2024

Genera in Madrid, Spain, 06 – 08 Februrary 2024

Some key takeaways from the Agri-PV and Floating-PV Summit in Rome!

ZIMMERMANN PV-Stahlbau named innovation champion

pv magazine top innovation: A new system for the new photovoltaic floating market

Company video of ZIMMERMANN PV-Stahlbau

References

Szeged – HungaryZIM2V, 2 Modules portrait, Inclination 25 °

43.998 Modules

23,97 MWp

Hungary

Start of construction: 2022

Zamosc – PolandZIM2V, 3 Modules portrait, Inclination 20 °

24.120 Modules

135 MWp

Poland

Start of construction: 2022